Fuel Polishing

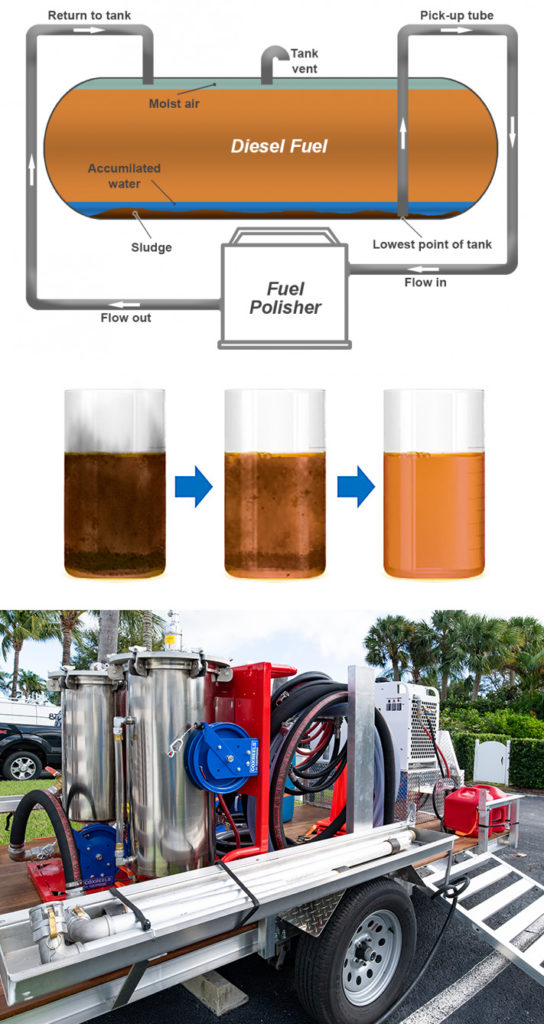

With the right equipment and expertise, dirty or water-laden fuels including both gasoline and diesel can often be restored to their original condition. The process, known as is fuel polishing, involves the use of specialized equipment to pump the fuel through filters and water separators, and the use of specific additives that remove any remaining residue for the interior surfaces of the tank.

With the right equipment and expertise, dirty or water-laden fuels including both gasoline and diesel can often be restored to their original condition. The process, known as is fuel polishing, involves the use of specialized equipment to pump the fuel through filters and water separators, and the use of specific additives that remove any remaining residue for the interior surfaces of the tank.

Palm Beach Marine Fuel’s fuel polishing services begin with an analysis of the contents of the tank or tanks to determine the nature and extent of the problem, and whether or not the fuel may have deteriorated to the point where it is no longer salvageable and must be pumped out and disposed of. In most cases, fuel can be saved.

Polishing equipment is brought on-site and is used to remove contaminants and water, including water that accumulates at the bottom of the tank and any water that is still emulsified in the fuel. Our systems are able to remove suspended water to an industry-leading 100 parts per million. In addition to water separation, polishing equipment filters out the biological matter, asphalt-like sludge, and other solids down to 1 micron in size.

To prevent future contamination, biocides and other additives are injected into the fuel as it returned to the tank. The exact mixture of additives will vary based on fuel analysis and circumstances. Some additives are designed to remove residual contaminants from the walls of tanks and internal baffles, while others eliminate microbes.

Palm Beach Marine Fuel deploys state-of-the-art fuel polishing systems. In addition to a high-volume system designed for industry and large vessels, we also provide compact systems that can be used at businesses, private residences, marinas, and other locations where space may be limited.

Download our Fuel Polishing brochure >here.